Water is a critical component of a wide variety of industrial processes. It can be used as an ingredient in a final product, as a cleaning agent to prepare equipment or materials for use or reuse, and as a reagent for analytical purposes. Because it is used in so many ways, it is important to consider water quality in terms of the presence of microorganisms. While it is tempting to presume that water is not subject to microbial contamination in the same way as more nutrient-rich or hospitable substrates are, this is not the case: in fact, microorganisms can grow and propagate in pure, and even ultrapure, water.

There are several ways in which microorganisms growing within a water purification system can impact water quality. For example:

- They produce undesirable metabolites such as pyrogens, RNAse, and other enzymes that can adversely affect the product that the water is used in.

- They can grow through 0.22-um filters, thereby impairing the ability of the filters to remove microorganisms from the water.

- At sufficiently high titers, many microorganisms can form biofilms that are highly resistant to elimination, can promote the growth and proliferation of pathogens, and may periodically detach and be released into the water stream, resulting in sudden peaks of contamination.

Contamination of water affects not only analytical techniques that the water is used in, but also secondary items and processes such as culture media preparation and equipment/glassware cleaning. Because of this, it is important to monitor water quality to ensure that the water’s cleanliness and microbial contamination levels are acceptable for its intended purpose.

Water quality requirements

Many water purification systems are monitored continuously for a variety of water quality indicators, and automatic alerts are triggered by the system when out-of-the-ordinary levels are detected.

The settings used to define what level of water quality is acceptable can vary depending on the sensitivity of the application and the level of quality needed. Water used in industrial, clinical, or laboratory settings is typically classified as being one of three types, as follows:

- Type 1, or ultrapure, water is the most pure type and is suitable for use in HPLC, cell culture, mass spectroscopy, and other applications that require a very high level of purity.

- Type 2, or pure, water is typically used for making media, buffers, and other solutions that are less sensitive to water quality than those listed above.

- Type 3, or primary grade, water can be used when cleanliness is required but high levels of precision are not, such as for filling water baths and cleaning glassware.

Somewhat confusingly, different water quality standards use similar terminology to denote slightly different things. One of the most widely used standard is that delineated by ASTM International. The most recent version of the document defining these standards, ASTM D1193-06(2018), was published in 2018. ASTM International defines water purity using a scale ranging from Type 1 to Type IV that takes into account a variety of factors such as conductivity, pH, and mineral content. It also provides a substandard that assesses the level of microbial contamination based on the amounts of heterotrophic bacteria and endotoxin (a bacterial byproduct) that the water contains.

The other most commonly used scale is the ISO standard for water for analytical laboratory use, the ISO 3696:1987, which was also updated in 2018. The ISO scale defines Grade 1 to Grade 3 water qualities, with Grade 1 being the highest. Similar to the ASTM standards, the ISO standard assesses a variety of water properties; however, it does not specify appropriate or tolerable levels of microbial contamination for the different grades of water.

Water treatment process and water quality monitoring

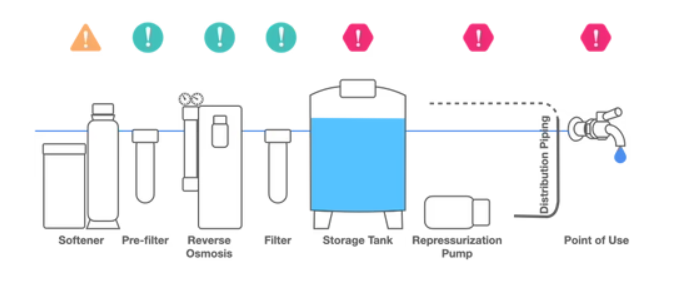

Purification systems employing a number of distinct purification technologies are used to achieve water quality levels in line with the standards described above. Ideally, the water purification system will address a range of contaminants, such as minerals, organic compounds, and particulates, as well as of course microorganisms.

To specifically eliminate microbial contamination of water, an optimal water treatment process will use techniques such as:

- Reverse osmosis (RO), which forces water through a membrane with very small pores that block the transit of most bacteria and viruses.

- Ultraviolet light, which kills bacteria and viruses directly (although this approach does not remove killed microorganisms from the water). UV lamps emitting 185 nm wavelength generate ozone from oxygen, an oxidizer that kills microbes, while lamps emitting at 254 nm target the DNA of viruses, fungi and bacteria.

- Filtration, generally with a 0.22-um filter, which removes bacteria from solution.

Maintaining a high flow by designing the purified water distribution through a recirculation loop is an efficient way of maintaining water quality. Preventing water stagnation limits the potential formation of biofilms.

Noticeably, ion exchange, typically mixed-bed, and either single-use or regenerable, which removes charged ions from solution have no effect on microbes and can even be in some circumstances a source of microbial prolifération.

Unlike other contaminants like particulates or dissolved minerals, removing the majority of microorganisms is not a permanent step, as trace amounts can repopulate the water to generate detectable levels of contamination. Thus, systems should ideally be monitored continuously for the presence of microbes to ensure that the different techniques that are applied are effectively maintaining the microbial content at levels low enough that they will not have a negative impact on the final product.

Unfortunately, the majority of existing monitoring systems are not designed to assess the level of microorganisms. Thus, the need to constantly maintaining water purification systems, and monitor microbial levels in particular, can represent a substantial burden for a busy organization. Fortunately, standalone monitoring systems are now available that are easy to use and do not require any specialized equipment or laborious manual recording. Integrating such a system into your water purification process could be the key to successfully preventing regrowth of microbial contaminants in storage tanks, distribution piping, and other equipment.

Conclusion

- Water quality is critical for many applications, and microbial contamination is a serious threat to the quality of water used in a range of industrial processes.

- The presence of microorganisms in a water purification system can impact the water quality in several ways, such as the production of undesirable metabolites, impairment of filter function, and formation of biofilms.

- Many currently used water quality indicators can be measured continuously by the water purification system and trigger automatic alerts when levels exceed the specified limits. However, most commonly used indicators do not assess the level of microbial contamination in water purification systems, so an alternate approach is needed.

- Maintaining the cleanliness and sterility of water purification systems, and monitoring microbial levels in particular, can be a burden for a busy organization.

- Easy-to-use, stand-alone, equipment-free, and pen-free monitoring solutions are now available that can record and analyze microbial counts to help prevent microbial regrowth in storage tanks and distribution piping.