A major European paint producer with a reputation to protect

Paintex (name changed for the confidentiality of the business) manufactures paints for a variety of dealers throughout Europe.

While it may surprise the layperson, microorganisms can grow and multiply in paint, degrading its quality. The literature suggests that major groups of microorganisms involved in paint deterioration are bacteria and fungi, which can grow on applied paint films and solvent and water-based coatings. Most commonly isolated bacterial species in paints include aerobic Bacillus, Pseudomonas, Enterobacter, Proteus, Escherichia, Micrococcus, Serratia, Aeromonas, anaerobic Bacteroides, Clostridium. Additionally, Rhizopus, Aspergillus, Penicillium and other fungi are associated with the deterioration of paints. The majority of these organisms are ubiquitous and can be found in air and water.

A customer complaint reveals a testing need

While Paintex has an excellent reputation (to protect!), it has fielded complaints from customers before. In this particular case, an end-user made a complaint, leading Paintex and one of its dealers decided to investigate the potential microbial contamination of a particular batch during manufacturing.

At the time, Paintex did have a quality control lab, but no technique for microbial testing.

A punctual investigation in case long-term monitoring is needed

The customer-complaint established an urgent need for Paintex to implement a microbial testing method for its investigation, but if findings suggested the production process was vulnerable to contamination, the method could be and should be shifted into a continuous monitoring program.

Testing nomad devices on a highly viscous and hard-to-filter liquid

When the investigation was about to take place, nomad HPC test devices were already well-suited for the detection and enumeration of environmental flora including aerobic bacteria and fungi, but their applicability to paints still needed to be demonstrated.

The nomad devices provide quantitative and qualitative results based on the membrane filtration (MF) technique and so require the draw of 1 ml of sample through a 0,45um filter.

Sample flow through a membrane filter behaves in a similar fashion as through a large number of small capillaries and can be simplified as Flow = X / Viscosity when pressure, temperature, filtration surface are constants.

Paint, however, with a viscosity around 100 centipoise is 100x more viscous than water, and therefore very hard to filter.

In theory, based on the filter water flow characteristics, with around 1 bar differential pressure, sampling 1 ml of water takes around 8 seconds, close to the observed time.

In theory still, filtering the same volume of undiluted paint would take close to 15 minutes, and over 2 minutes for a 10x-diluted paint.

Another specificity of the nomad design is that, contrary to lab MF techniques, which use a vacuum as the driving force through the filter, the nomad device’s driving force is absorption driven by the pad sealed under the filter. Capillary pumping of a liquid sample is meant to result in a more constant flow rate over time than a vacuum force, and regardless of the sample viscosity and surface energy, giving hope of a favorable outcome.

That’s for the theory, but as Einstein puts it: “In theory, theory and practice are the same. In practice, they are not.”

Diluting for results

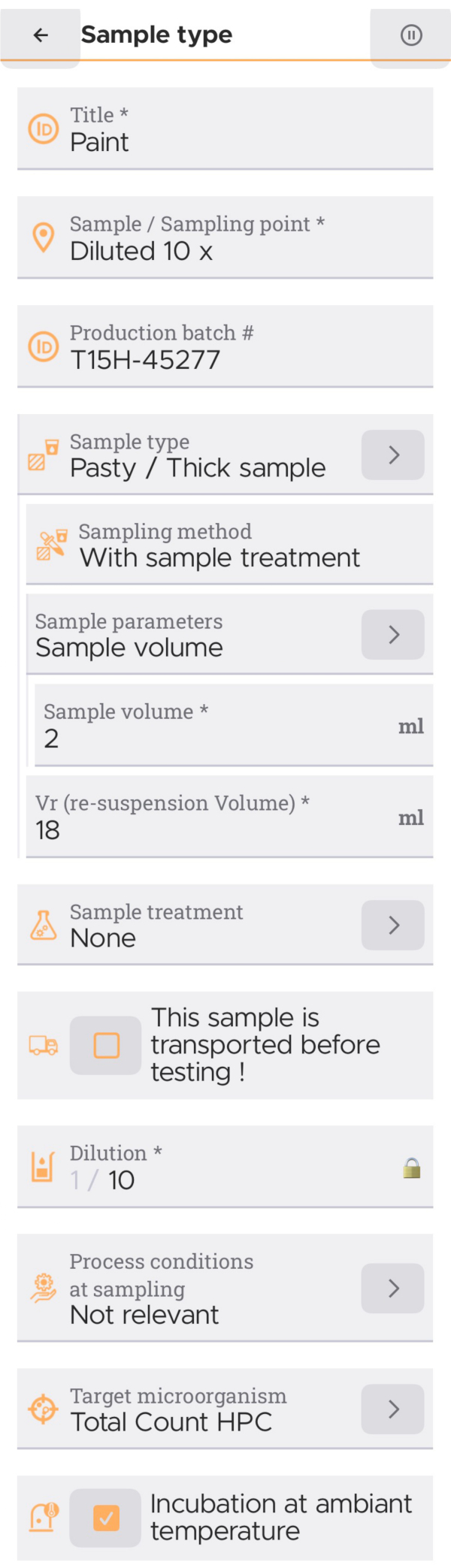

Paintex made serial dilutions of paint samples in sterile water which were then tested with the nomad IoT HPC testers and the Smart Microbiology Mobile App.

At the same time, production water was also tested.

Better in practice than in theory

The time necessary for the absorption of 1 ml of 10x-diluted paint, verified by weight and by the end of air bubbling through the devices vent, was approximatively 30 seconds. This was substantially shorter than anticipated by the viscosity vs flow calculation.

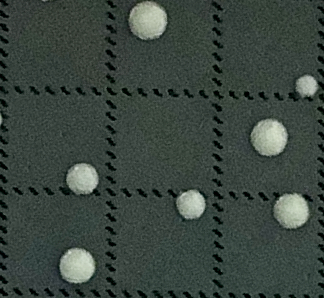

The process water result: 10cfu/ml, among which 1 mould, 2 types of bacteria whose appearance suggested their origin was from the environment (they didn’t have water as a natural reservoir).

The paint results: <10 cfu/ml, indicating the contamination level was low, i.e. the paint batch was not subject to microbial proliferation.

Note: the light green paint coated the devices filter and consequently the AI-based AutoCount colony counting feature offered with the Online App was taken off-guard. Counting was therefore completed manually on the results picture.

Mutual testing for contamination produces more evidence

The nomad devices showed themselves to be an appropriate solution for testing paints, which could be applied by Paintex and the involved dealer, in order to provide evidence for the complaint investigation.

Working together down the supply chain to test for contamination

Sharing tests methods between supplier and supplied can benefit troubleshooting and help in locating where an issue originates in the supply chain: expedition, transport or reception.

The same principle may be applied to ordinary hand-over of equipment after a sales transaction or maintenance. Facts are a good place to begin to establish peace of mind.

This case is a reminder that water supports life: give them even a small chance and microorganisms will grow when there is water, hence the importance of controlling process water and water-based chemicals to monitor their contaminating flora.

nomad Test Kits show their application for other viscous liquids

Since the nomad devices rely on capillary forces to drive sample filtration, they are suitable for a diversity of otherwise difficult to filter samples such as syrups, ointments, or emulsions and by extension to solutions containing soft matters such as suspended ground meat or pulp.

Microbe-wise – A quick look at Micrococcus

Micrococcus occurs in a wide range of environments, including water, dust, and soil and have been isolated from human skin, animal and dairy products, and beer.

Most are mesophile and grow best at moderate temperature, neither too hot nor too cold, with an optimum growth range from 20 to 45 °C / 68 to 113 °F) and they can grow well in environments with little water or high salt concentrations.

Though not a spore former, Micrococcus cells can survive for an extended period of time, both at refrigeration temperatures and in nutrient-poor conditions and are capable of forming biofilms.

Disclaimers

This Use Case is based on a true story! (Though we edited it for readability and, of course, for confidentiality.) We like to share stories about real situations because we think they help translate raw facts into helpful insight and understanding. We’re providing this use case as an illustration, but it does not imply that the same conclusions can be made in similar cases. We will be happy to discuss it, however, as well as how the particulars of this case might be transferable to your situation—so don’t hesitate to contact us! Also, please be aware that we do sometimes use automatic translations, which might slightly distort the information.